Current development project

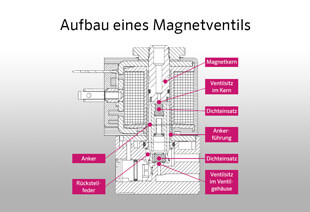

Solenoid valve (3/2 way NC) for gearshift mechanisms in commercial vehicles

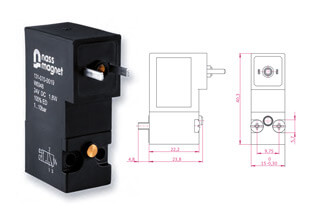

The new solenoid valve (3/2 way NC) is to be used in a pneumatic control unit. This controls different pneumatic cylinders in heavy goods vehicles, which in turn are connected with the gearbox mechanics. This replaces a hand on the gear lever, so to speak. In addition, the valve primarily serves to save fuel and keep emissions in commercial vehicles below threshold values in future.

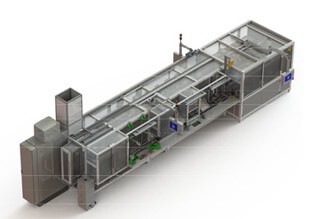

The plant for producing the solenoid valves is under construction at the nass magnet GmbH factory in Hanover. A highly automated plant is being developed, which has a capacity to produce 2,400,000 solenoid valves per year at its first expansion stage. Production is planned to start in 2020, after trials and approval by the customer.

Trials and coordination in heavy goods vehicles is an extensive task. nass magnet requires a huge number of sample parts — over 7000 in total. This presents us with a major challenge, since the samples always enter the HGV in certain trials on fixed dates (e.g. winter or summer tests).

It is also essential for sample parts to be high-quality, since they are the key to the success of this kind of project. If samples are defective, an analysis has to be performed to establish the reason for the part failing. From the analysis, measures have to be pointed out to the customer that can be taken to prevent a defect at this location in future. The optimisations are integrated in the next samples and series production equipment. For the HGV winter test in Sweden, nass magnet ordered a further 1700 solenoid valves. These are currently being built and supplied. The schedules specified are very tight, but so far we have been able to meet them.

Some dates at a glance

- Delivery of individual components from series tools – 1st quarter 2019

- Construction of test facility (End Of Line) – 2nd quarter 2019

- Commissioning of plastic machine – 2nd quarter 2019

- Delivery of winding system – 3rd quarter 2019

- Completion of production plant – 3rd quarter 2019

- First delivery of prototypes for customers – 3rd quarter 2019

So far, we have received a lot of positive feedback from the customer, however there are still tasks to be accomplished before series production can begin. Thanks to close cooperation both internally and with our customer, as well as willingness to present new solutions quickly, we have been able to show our adaptability — in this case we were THE leading manufacturer for our customer.

Current plans show a second plant beginning production in the year 2023. This will expand capacity to 4,800,000 solenoid valves per year.

Tino Wiggers

Project management, nass magnet GmbH