Little ABC of nass magnet's products (Part 2)

How is a Solenoid Valve constructed?

What at all is a solenoid valve? - That was the question in the first part of our small technical series about the product from nass magnet that is very appreciated by many customers.

The answer was "...that a solenoid valve is a kind of pilot for the main valve with clear instructions for the gas: There is the way... right now! And now not. And so on."

In the following we address the question how a solenoid valve is constructed.

Who wants to know something about a product should ask its developer. And how do we know that the answer is right? This question is rather easy to answer for technical products that are subject to the laws of nature and are not only produced, but also sold and used: Look into the face of a customer who has bought and used the product in question!

In his presence, say loud and clear the name of the company who has produced and sold the product in question. Shows the customer a satisfied expression or even a respectful smile, the developer must probably has not told you nonsense. But you'd better get a second opinion and repeat the procedure at another customer. If you find a "smiley" here, too, everything is OK.

In case of nass magnet/nass controls there have always been many satisfied customers, regarding function and performance data of solenoid valves.

Well, let's ask the pros how such a solenoid valve is actually constructed. - In the presentation "Physik live bei nass magnet" for pupils of grammar schools in the Hannover region it sais: "a solenoid valve consists of a solenoid coil (electrical part) and a valve system (pneumatic part).

The solenoid coil, the electrical part of the Solenoid Valve

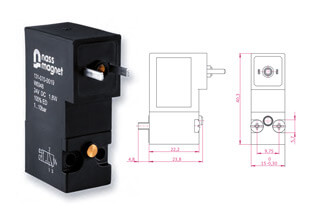

Let's clarify in the beginning what such a solenoid coil, the electrical part of the solenoid valve, looks like in its simplest form:

On a coil body (rectangular or cylindrical tube with or without side flanges) an enamelled copper wire is wound. The coil body will then be equipped with pins so that the wire ends can be connected electrically. An insulating material around the winding serves for the required electrical and mechanical safety.

Depending on the needed power (measured in Watt or Voltampere) and frequency (repetitions, measured in Hertz), the winding of a solenoid coil varies in thickness of wires and number of windings. A coil is always designed for permanent operations (100% relative duty cycle). Is the solenoid coil used in special environments, like for instance explosive areas, also the enamelled copper wire must be madefit for extremely high temperatures, if needed. This is called anodization.

The task of a solenoid coil is described in short words on the website of the company group nass magnet as follows: "Part that contains the excitation winding and conducts the magnetic flow." The magic word is inductance, which is the main characteristic of coils.

Explanation: Every energized conductor contains closed, circular magnetics, this magnetic field is very small. To increase its intensity, the wire is wound on smallest room.

Through the increasing number of windings the magnetic field lines per unit overlap inside the coil. Through this measure the inductance of a coil increases. The inductance depends on the number of windings, that means, how strong the produced magnetic field is. So inductance is the measure of the strength of a magnetic field of a coil.

The inductance can also be influenced by the following measurement: A core made from ferromagnetic material, like steel, is inserted into the coil. This results in a higher magnetic flow inside the coil and a much stronger magnetic field. And so the engineer becomes thriffy: Considerably less windings of the enamelled copper wire are needed. Less volume of the components are needed and nevertheless the required inductance is achieved. Little reservation: The trick is restricted. Because the magnetic flow, depending on the used material, will give the signal: "Problem, I am saturated!" at a certain time. An engineer calls this state saturation magnetization of the core.

The valve system, the pneumatic part of the Solenoid Valve

And now for the pneumatic part of our solenoid valve: What is the typical construction of a valve system? Let's take another look at the website of nass magnet: "...consists of armature system and valve body with the corresponding pneumatic interfaces: KR (concentric O-rings), GKR (concentric O-rings with internal exhaust), CNOMO, SF (side flange), FL (flange with O-rings)."

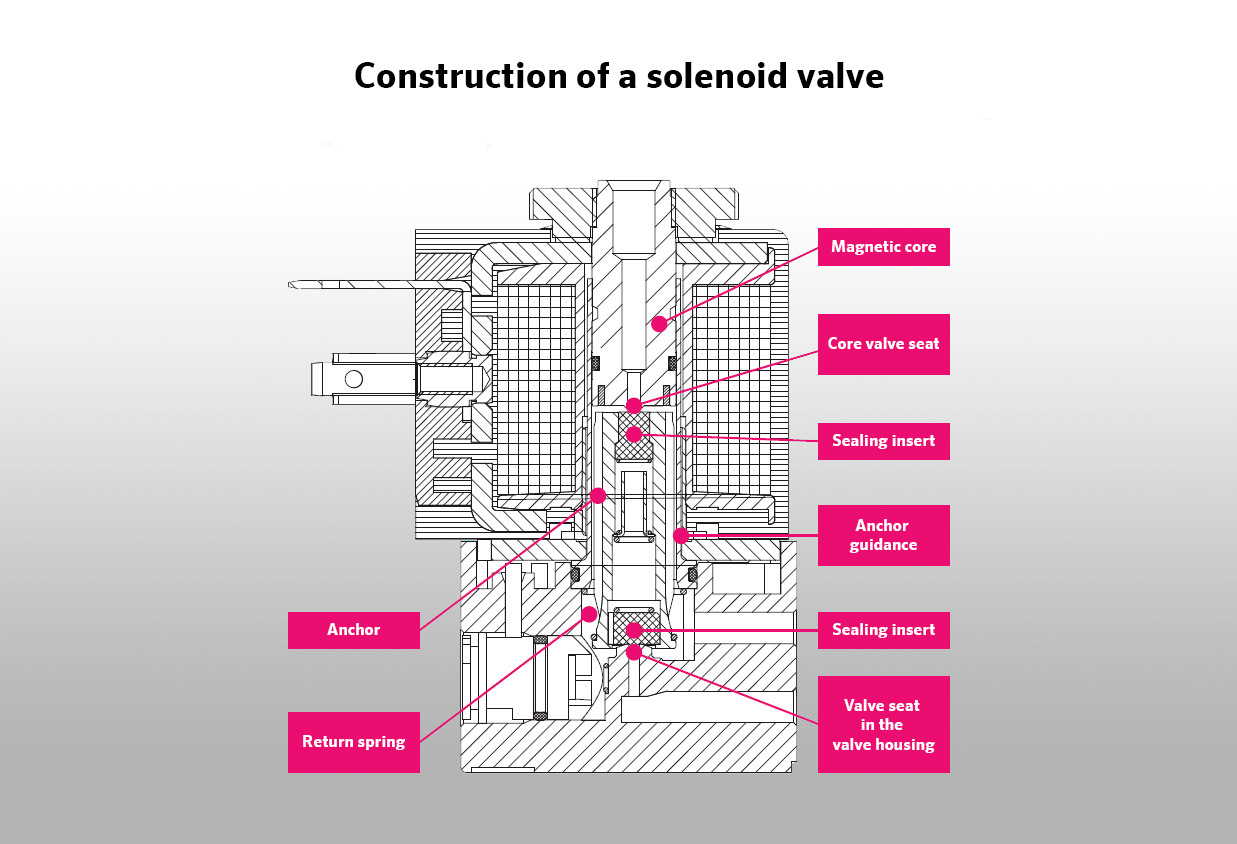

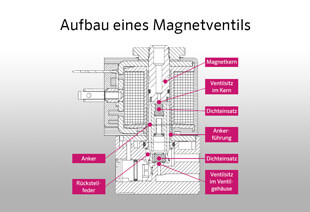

Please have a glance at our graphic. - An armature assembly consists of an armature guide, a magnetic core and an armature with its return spring. In addition in the armature there are one or two sealing elements that seal the respective valve seats and that ensure the allowed leakage - best would be zero. The valve body is the pneumatic interface to the armature system.

The simplest version version of the valve with two ports and two switching positions is called 2/2 way valve. Normally opened systems (NO) are kept in the open position through spring force - the pneumatic media (gases) find an open way - and are closed through the magnetic force.

Normally closed valves (NC) are closed through the spring force - the pneumatic media (gases) find a closed way - and the magnetic force opens the valve.

Does everything go as planned?

Our solenoid valve is already finished. Almost finished. If everything is assembled, extensive tests have to be carried out before they can be shipped to the customer. This belongs to the basics and matters of course at nass magnet. Because innovation without control - that does not work at all!

Since it is about top products as described in the beginning, that must work without problems and conjure up a smile into the faces of our customers.

Finally the customer can use the solenoid valve in his application. There are various possibilities for an application. Some of them will be introduced to you in the next part of our little series about nass magnet's products...