Twin Boost production

Expanding production equipment for special operating facilities

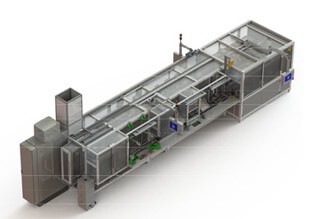

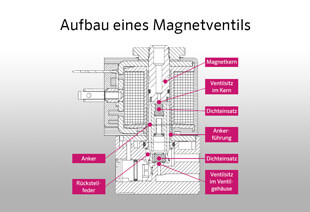

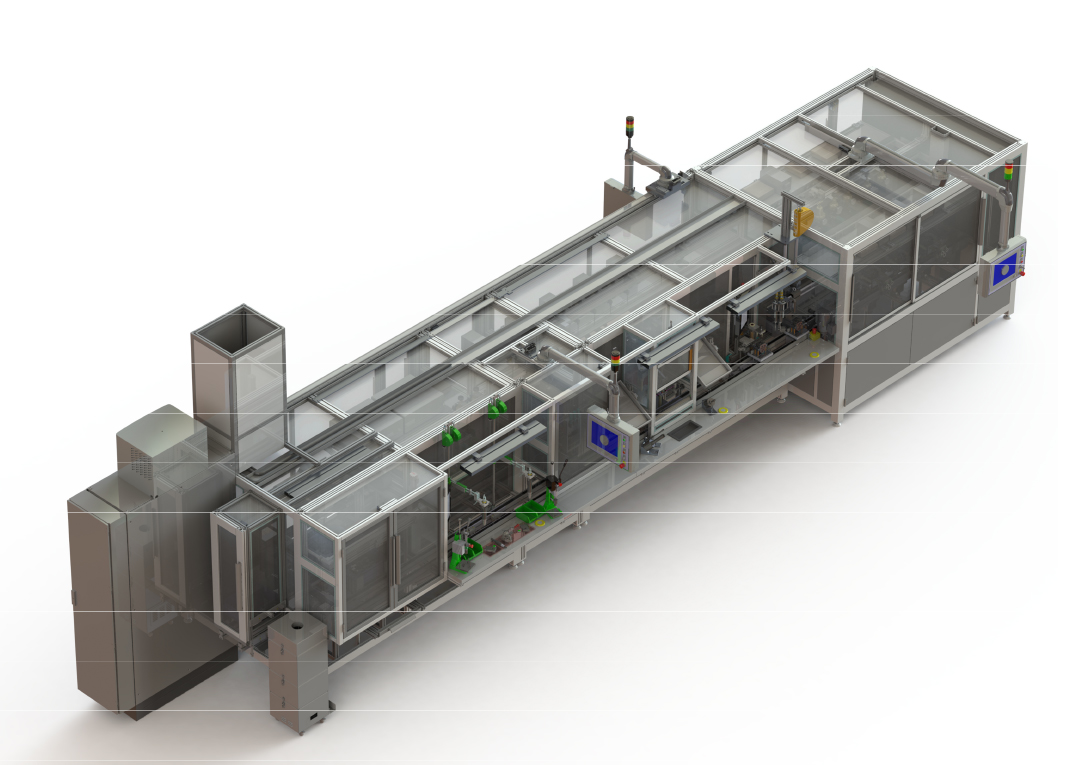

For a long time, we have been operating an extensive assembly line for producing „Twin Boost“ pneumatic spring control units for cars at our site in Hungary. Our customer‘s demand for this type of product is steadily increasing. The high reliability of our product as well as our very good customer supply and support systems contribute to our customer‘s ground-breaking success, who thus became a market leader in this sector.

Our combined, outstanding performance led to the development of new versions for other automotive manufacturers, increasing lot sizes and the assignment of additional production capacity.

The cost of assignment of special operating facilities, e.g. welding, assembly and testing facilities, has increased to many hundreds of thousands of Euros each year. Planning, project management, realisation, sales, commissioning, operation and maintenance amounts to a lot of challenging work for us. This growth is the pay off — together, we are doing a great job.

In 2020, the Covid crisis changed everything

Due to travel bans, our Hungarian colleagues are currently no longer able to attend the training and disassembly courses at our Hanover plant. Due to the lockdown, our Hanover colleagues are also unable to supervise the assembly, commissioning and approval on site in person.

However, even in these times (or maybe especially in these times), we are strong together. New ways had to be found, considering our equipment is worth almost a million Euros. This was a highly challenging task both technically and in terms of time pressure. Teams from all divisions and sites came together online to decide on what to do. In order to maximise awareness, understanding and exchange, videos were made and all project meetings were moved online.

With a lot of effort, our aim of creating a commissioning process which met all customer requirements, was finally achieved.

During the pandemic, it once again became clear how flexibly and excellently we work together as a team and that no hurdle is too high when we work together. When we all turned our combined energies towards the task at hand, we identified the risks as well as the opportunities and came up with solutions. The first time we transferred online was a success across the board — we managed to satisfy both sites and our customer.

This is heading element

With this report, I want to warmly thank everyone involved, in both Hanover and Veszprém.

It was and remains wonderful to see the way we work together, supporting each other as colleagues, almost like a family.

Therefore, I look towards future challenges with positivity; even now, another two plants are ready for transport. And I am already looking forward to the day we can finally meet offline and in person again.

Stay safe.

Marco Biester

Head of Process Technology, nass magnet GmbH