Cobot opportunities

Taking the weight off our colleagues instead of intimidating them

In order to remain competitive, it is really important, among other things, to keep up with technological developments and stay open-minded towards new technologies. New technologies can support our colleagues, reduce their workload and improve quality. One of these new technologies are cobots — small and large robots whose job it is to take some of the load off our colleagues. The aim is for the cobots to improve working conditions for people — not to replace the people.

What does „cobot“ mean?

One subject which is gaining increasing traction in the industrial sector is human-robot collaboration (HRC) – people and machines working together. HRC is implemented using so-called „cobots“. The term „cobot“ stands for „collaborative robot“.

Cobots are industrial robots which work together with people on production processes without being separated from them by safety equipment. With the help of integrated sensors, cobots can work side-by-side with humans.

Cobots are flexible and are distinguished by their user-friendly interface, which makes them easy to program. In contrast to an industrial robot, anyone with a certain level of technical expertise can carry out the programming without needing to attend a training course first.

Cobots have a huge variety of available accessories. Plug-and-play systems from a variety of manufacturers enable the simple integration of extensions (such as gripper technology, camera systems, etc.) and speedy conversions to tackle a range of applications.

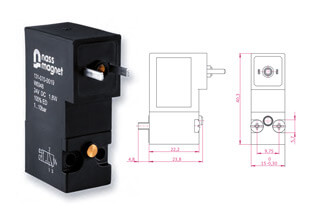

nass magnet invests in articulated robots

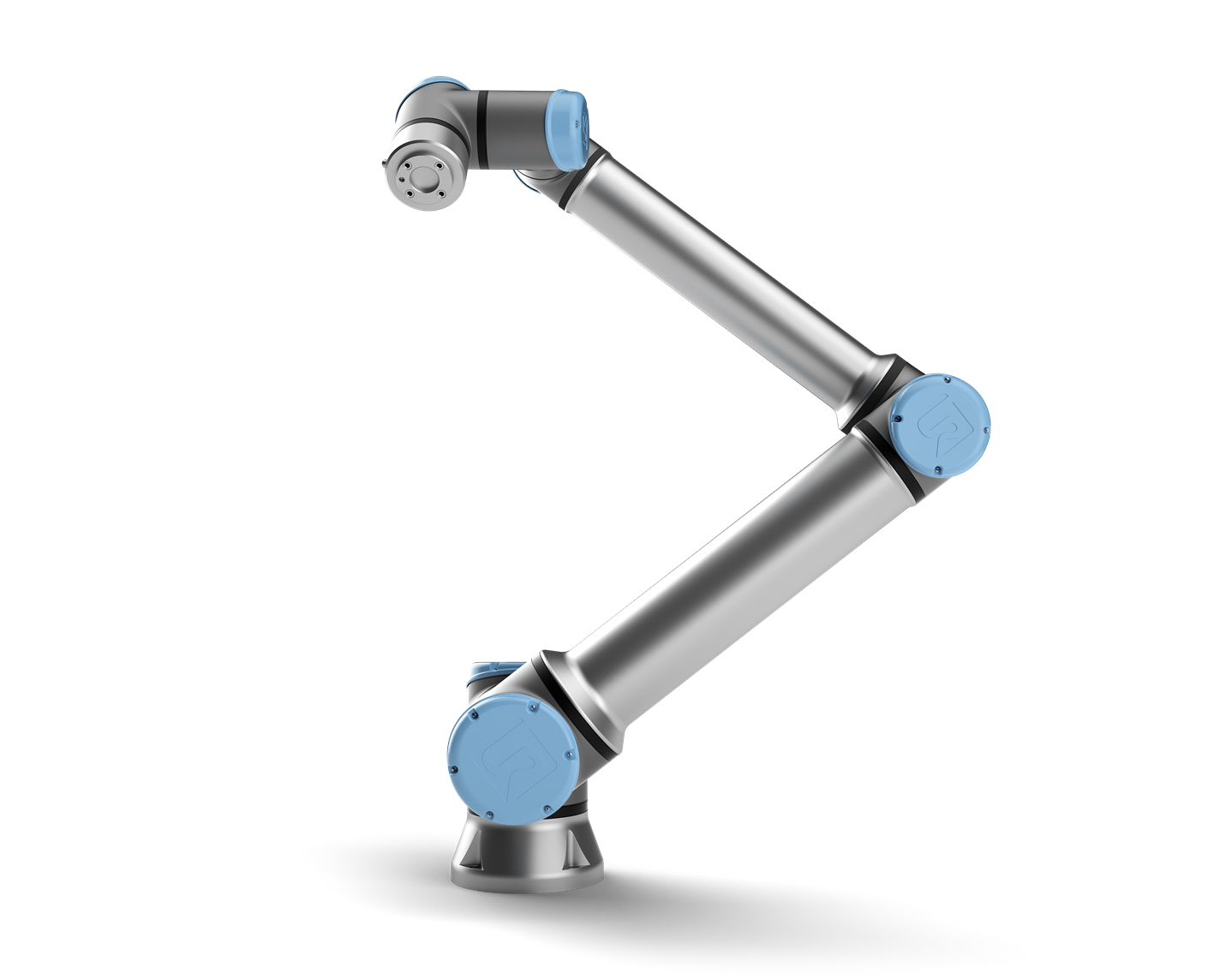

Our cobots belong to the serial kinematics type, so-called articulated robots. These usually consist of between five and seven rotary joints arranged in a row, which are comparable to a human arm. They vary in terms of size, load capacity and number of joints.

The number of joints defines how well a robot can move around its working environment and avoid potential obstacles. A large selection of collaborative robots is now available on the market from a wide variety of manufacturers.

Cobots take the load off our colleagues

In order to decrease the workload of our colleagues and free them from monotonous tasks, this topic is being closely followed by a team made up of production and process development workers. It is their job to investigate the opportunities a cobot would offer us, how it would improve the quality of our processes and products and, above all, how we can use it to support our colleagues and decrease their workload. in doing so, collaboration between people and the cobot is at the fore.

Over the last few months, the team has been intensively concerning themselves with this subject. As part of this, they conducted extensive research. This included probing the cobot market and coming up with possible ways in which it could be utilised within the company, in order to carry out a subsequent cost-utility analysis and identify the right manufacturer for our company.

As part of this, among other things, we also worked together with the company ibk IngenieurConsult GmbH from Hanover and were permitted to extensively test two cobots from the manufacturers Kassow and Yuanda in their Innovation Lab in the northern German city. In addition, Universal Robots provided us with a device on loan for a week which we worked with intensively in our Process Laboratory. As a result of this research, we came to the conclusion that the Universal Robots cobot is the right device for us.

Practical cobot testing — helping out in the plastic injection moulding centre

In order to demonstrate whether and how a cobot can be integrated into our processes, we started a funded project in collaboration with TEWISS – Technik und Wissen GmbH in March. As part of this, a UR10e (Universal Robots cobot) was integrated in the plastic injection moulding workshop.

This cobot is a loaned device from TEWISS GmbH. It is capable of loading the injection moulding machine without assistance. Using the cobot in this area means colleagues working here no longer need to carry out a task which they find monotonous and unpleasant.

The idea of collaborative working becomes relevant here as colleagues will provide the cobot with material (flange plates) on a regular basis. This task is less strenuous for the human workers and takes less time. In this way, the cobot enables different tasks to be carried out in the mean-time.

The safety of our staff is always centre stage. That‘s why we informed the company‘s Health and Safety Officer and the Works Council of our plans early on and duly integrated them into the development process.

What is the next step?

The funded project gave us an added boost in our endeavour to acquire a cobot for nass magnet. We were able to show, with great impact, that there are plausible and valuable ways in which a cobot can be utilised in our company.

The plan going forward is to acquire our own first cobot and to continue working intensively in this field in future.

The aim is the seamless integration with our production processes and the relieving of our colleagues of the need to carry out repetitive, risky and physically uncomfortable tasks.

If you have further questions or want to know more about cobots, the process development team is at your service.

David Pilarski

Process Development, nass magnet GmbH