The Smart Connector

Innovation in valve connectors

Even our best products only remain successful if they are continuously developed. The technology used in our components continually confronts us with more and more challenges. The valve connector market expects innovative possibilities and functions, such as a timer or power regulation for voltage and current.

But how can all this technology be controlled in our compact components?

We have been tackling this problem over the past few years and have found a solution in the form of the industry standard IO-Link.

Communication via IO-Link

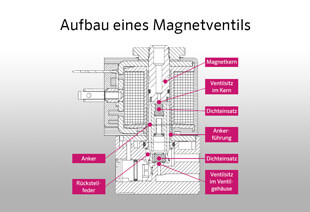

Alongside hardware development, the development of embedded software is becoming increasingly important at nass magnet. As the name „smart connector“ implies, the connector is an intelligent piece of technology and therefore requires corresponding software. Since this is not typically the case in our most common products, such as solenoid valves, we were faced with a tricky task: In order to use the software, users must somehow be able to operate it.

As a result, our aim was to develop a device that can be set up by the end user themselves. However, the small size of our parts means that it is difficult to integrate switches or complex user interfaces. We discovered a solution in the form of the industrial communication standard IO-Link. A functional prototype was ready in no time.

In 2018, the development process gained momentum. After an initial year of advance development and a number of visits to a range of specialist trade fairs and conferences, we were able to significantly expand both our professional network and our IO-Link expertise.

Together with a neighbouring development partner in Hungary, we constructed our first IO-Link circuit boards in 2018 and, building on this, smart connector prototypes.

As well as overcoming the challenges inherent in our product idea, the connectors also had to meet a number of other conditions, which we had to take into account during the development process.

The product needs to withstand extreme industrial conditions, such as overvoltages, excessive current consumption, temperatures between -10 C and +80 °C, or immersion in water up to 1 metre deep.

Additionally, other products must not be affected by electromagnetic interference emitted by the smart connector. Conversely, the smart connector must also not be excessively susceptible to electromagnetic radiation from other products, such as mobile phones or power cables.

The smart connector must work perfectly under these and other extreme conditions.

What is IO-Link?

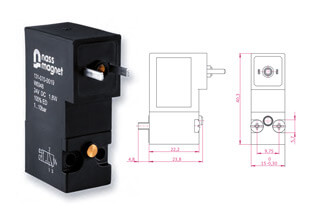

A manufacturer-independent form of serial communication, which was developed for industry; in many ways, it is very similar to the USB connection on a computer.

One of its advantages is that all that is required for connection is an M12 connector with the three-core unshielded wires commonly used in industry; two wires serve as a power supply and one wire enables the components to communicate with one another. The components communicate using a serial point-to-point connection between a master and the device. This means that the master queries and initiates, while the device (in this case, the smart connector) merely responds.

Users receive a device description file, known as an IODD (IO Device Description), which can be downloaded for free via our website. Using this file, the connection to the master and ultimately to the PLC is established – it can then also be used for parametrisation.

IO-Link technology offers direct access to the device (status, parameters), enabling Industry 4.0 or IIoT solutions to be implemented. From this point, the files can be sent to additional servers or to the cloud for further processing.

Putting the „smart“ in „smart connectors“

But what makes our connectors so smart?

To start with, they transmit essential information. The header of every product equipped with IO-Link communication contains information about the manufacturer, hardware and software versions, and serial number, among other details. It additionally specifies the website where further information can be found and where the product can be re-ordered.

Regular data transmission guarantees continuous functionality. The smart connector waits for the master to inform it whether the connected valve should be switched on or off and then tells the master whether the valve is in the retracted position or not. It also indicates whether certain parameters have exceeded the set threshold value. Additional product parameters can be read and written as necessary. Limit values for the current strength, temperature and even the maximum possible number of switching cycles for the controlled solenoid valve can be set. If the product exceeds these limit values, a message is sent to the operator via their PC; they can then implement any required measures. In this way, effective error diagnostics and preventive maintenance can be guaranteed. Errors are therefore detected before they occur. This eliminates unexpected downtime and repairs, saving significant amounts of money.

As well as enabling diagnostics on the PC and PLC, the smart connector can also communicate via the integrated, flexibly programmable RGB LED. This makes it possible to assign different colours and patterns (e.g. flashing, changing colours) to specific events, meaning that errors can be identified directly in the machine. Activating the „Find Me“ function integrated in the product causes the LED in the connector to flash in different colours – an extremely helpful function when looking for the connector within the system.

The data storage function makes it easy to replace the product, since the master stores the product settings and parameters, automatically installing these on the new smart controller after replacement.

Smart solutions are on the horizon

We presented the smart connector to customers for the first time at the 2019 Hannover Messe. On the basis of some very promising feedback and active interest on the market, we began 2020 by implementing series production and the approvals process that would enable the product to be sold worldwide.

This approval process is an extensive procedure, which requires a number of tests to be conducted externally. The fine-tuning steps were performed in the final phase. The approval tests are expected to be completed in Q3 of 2021 and SOP is planned for Q4 of 2021.

Although the development work on the smart connector is not yet entirely finished, one thing is already very clear – it certainly won‘t be the last smart product from nass magnet.

We are also contributing to the development of a state-of-the-art Enterprise IoT system; our aim is to offer customers real added value in the form of functions like condition monitoring and preventive maintenance, thereby helping them to stay one step ahead of their competition.

Zsolt Tasner

Head of Development HU,

nass magnet Hungária Kft.