Mastering crises together

Strong team spirit, even when the building is on fire

When we won the project for our customer Wabco – which will in future provide an annual turnover boost in the tens of millions for our company – it became clear that the space available at Eckenerstraße 4 – 6 would soon be too small to set up the necessary machines.

A quick decision had to be made in order to ensure that the ambitious scheduling targets for the project were not put at risk. It was therefore not an option to wait to see whether the neighbouring Metro Gastro wished to continue as a tenant at their current location. This wholesaler has until the end of 2018 to unilaterally decide whether to rent the property until the end of 2025. If they were to choose to leave this would naturally resolve the space issue, but it was not possible to wait until this decision was made.

A proposal to expand the production site in Hungary was rejected for the time being, as the close link to product and process development, which is particularly necessary during the expansion phase, could not be guaranteed. This meant that the solution was obvious: New premises were required. However, this raised the question of which parts of the company could be relocated to the new premises. A concept prepared by Head of Logistics Dierk Dreyer and Head of Production Carsten Meinhardt provided clarity: The most logical allocation would be to relocate the Logistics department. The search began and proved to be rather difficult, given the already strained Hanover property market. The available premises were either too far away, too large or too small – there was always something that was not right. After some time, we were offered the depot of the former „Boss“ furniture store on the Alter Flughafen business park. Several viewings quickly made clear that this was the most suitable warehouse space for us. Large enough, located close to our main plant and structurally sound. In addition, the workmen provided by the lessor meant that the available space could be swiftly converted to ideally suit the needs of nass magnet GmbH.

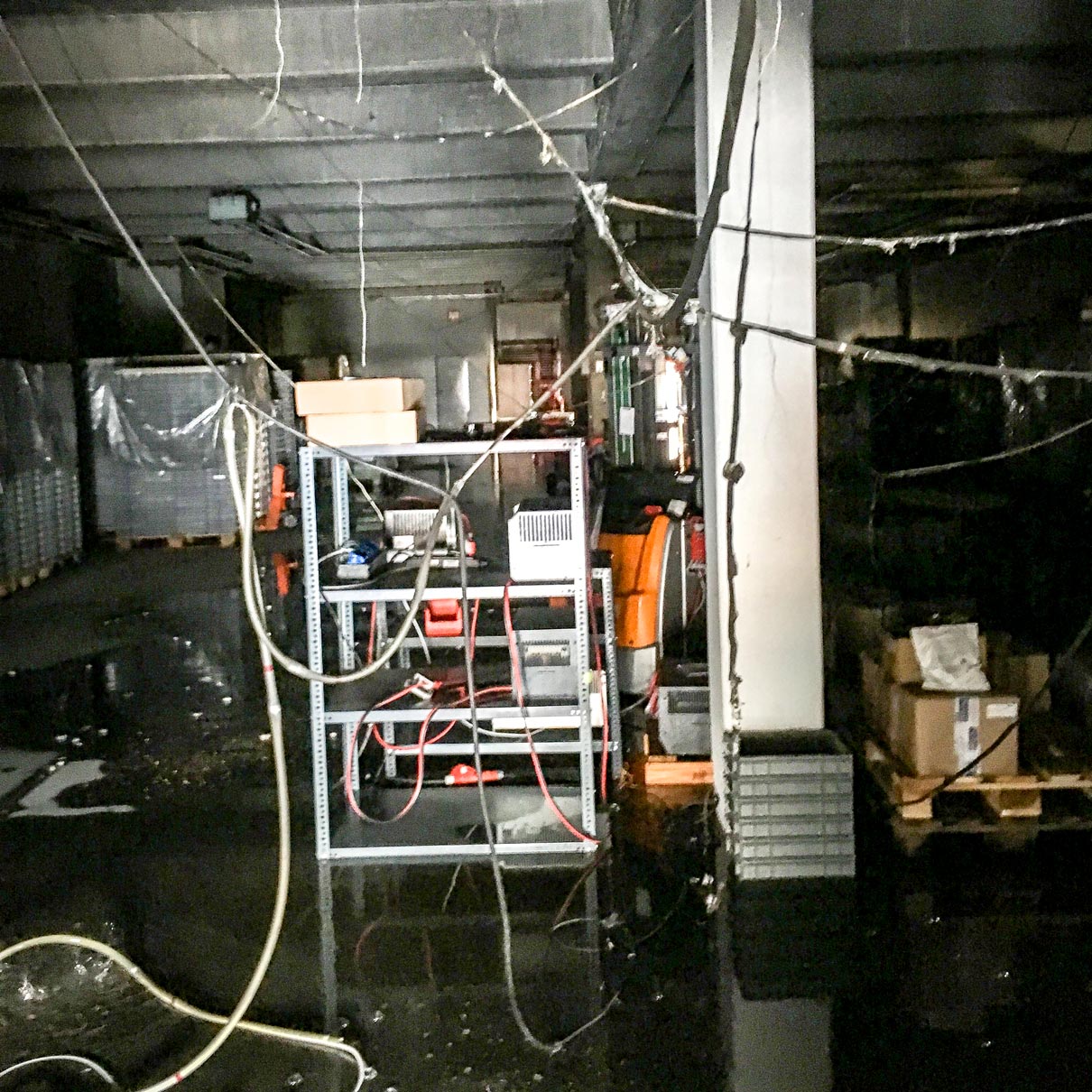

Consequently, November 2017 saw warehouse 10 Alter Flughafen completely cleared out and gutted. In December, the warehouse was provided with interim electrical fittings and an IT installation and set up to ensure that the premises were prepared for initial use.

The move took place at the end of the year and the new nass magnet GmbH warehouse was ready to be put into operation in January 2018.

On the 15th February 2018, at around 5:30 pm, Dierk Dreyer and I even spoke on the phone about how fast and successful the relocation to the new warehouse location had been. At that point, everything was indeed running smoothly, and all the obstacles and teething problems had been overcome.

But how does that famous expression go? Don‘t count your chickens before they hatch. Roughly two hours after our phone conversation, I received another call from Dierk Dreyer. He informed me that he was already heading back to Hanover from his home, because our new warehouse was on fire. I immediately set out for the scene of the fire and arrived there shortly after Dierk Dreyer, having informed my colleagues en route. Arriving at the scene, I saw that Dierk Dreyer was already busy saving as much as possible from the danger zone. This also made it possible to remove our 7.5-tonne truck – purchased for moving goods – from the danger zone. However, it was quite impossible to access our storage areas, and strictly prohibited as well – understandably enough.

A gigantic fire was raging; three fire engines from the professional fire department and several voluntary fire departments with 78 emergency vehicles, including three turntable ladders, a 54-metre-high telescopic platform, mobile water cannons, large-tank firefighting vehicles and 240 officers were involved in the firefighting operation. The fire had obviously broken out within the building complex, but not in the sections of the building we were using.

Little by little, more colleagues arrived on the scene. A small initial crisis meeting was held once Patrick Oelkers, Bernd Schönemeier, Marco Biester and Carsten Meinhardt were present, in addition to Dierk Dreyer and myself. Shortly after, my daughter Felicitas also arrived, with sufficient food for the small „nass magnet fire team“ in tow.

Status meetings were held each hour in the mobile operations centre of the Hanover fire department. At around midnight, the officers were able to bring the fire under control and we headed home – with the exception of Dierk Dreyer, who remained on site. Arriving home, I prepared a report at around 0:17 am for the Sales, Purchasing and Holding departments and our insurance agents, highlighting — among other aspects — that all customers would have to be immediately informed that a force majeure event had taken place in the form of the fire. A large part of the side of the warehouse we were using was still standing and the impact of the extinguishing water had been kept within limits. Nevertheless, nobody was able to enter the warehouse until Friday afternoon in order to ascertain the extent of the damage and the usability of the remaining raw materials and finished products, neither were any logistics providers going to be able to call at the premises. Urgent requirements in the short term and potential surcharges on production materials had to be clarified.

On the following morning, Friday 16th February 2018 at 7:11 am, the shareholders and Supervisory Board were informed that more than half of the entire warehouse, including the sections used by our company, had been destroyed by the fire. A meeting to provide information about the fire was held at 7:30 am that same morning, to which I had invited all the directors, authorised officers, heads of department and the Works Council. A request was made to clearly list all additional costs (materials, money, working hours) so that a claim for the effective cost could be submitted to the insurance company. The first urgently required emergency plans were drawn up.

In accordance with my request, our Purchasing department informed all of our suppliers about the fire and asked them to be on standby, in case we had short-term raw material or individual part requirements as a result of the fire and the consequent loss of goods.

At 2:30 pm on 16th February 2018, our receptionist Susanne Sroczynski informed us that we had received countless calls and e-mails from suppliers offering to help us and provide priority shipments.

Because access to the building had been barred by the police while the fire was investigated, we had to assume that we would only be able to enter it the following week. However, a section of the warehouse was already unbarred by Friday lunchtime. This meant that a large number of helpers from across every department were busy evacuating potentially usable materials from the site of the fire as early as that same weekend. Fortunately, Dierk Dreyer had found a small temporary warehouse with three rooms in Langenhagen, where goods affected by the fire could be placed. The plan was to keep one of the rooms aside as a cleaning and decontamination area right from the start. At the same time, our Purchasing department was working flat out to obtain raw materials from our suppliers in order to post-produce any goods damaged by the fire as rapidly as possible. Creating a cleaning area and storage space for the newly procured raw materials and materials affected by the fire within the warehouse space, now reduced from approx. 3500 m² to approx. 500 – 700 m², constituted a massive challenge.

The aggressiveness with which the fumes affected our materials could be seen in the fact that the forklifts, which had been salvaged from the scene of the fire along with a number of goods, had rusty forks after just two hours. For this reason, Dierk Dreyer took the precaution of cutting appropriate ventilation openings in the façade before evacuating the goods to ensure that they were adequately ventilated. In addition, all individuals tasked with salvaging goods had been supplied with respiratory masks.

On 17th February 2018, Dierk Dreyer announced that all the goods had been removed from the pallet racks and all but a small number of the pallets had been relocated to the inspection area; however, further goods were still waiting for removal and due to the latent risk of collapse and the destruction of all the cables coming from the ceiling, it was no longer possible to reach the goods using ground transport equipment.

We needed to clarify exactly how the goods should be appropriately and professionally checked, cleaned and repackaged. Furthermore, it was clear that we would be dealing with very high levels of contamination from fumes, as heavy corrosion was found and the fumes had also entered covered goods.

In our rented warehouse, unsuitable for our normal processing operations, the goods were separately stored in two sections of the warehouse so that they could be taken for cleaning and repackaging and thereby avoid cross-contamination.

In accordance with the procedure for responding to fire events circulated by our Product Safety Officer, Holger Last, a chemicals expert was immediately commissioned to assess our inventory and recommend a recovery plan. Together with this expert and the insurance specialist, further steps were coordinated on Monday 19th February and the goods were inspected.

On 19th February 2018, Christoph von Maltzahn was designated as the point of contact for all customers and sales staff for questions relating to the fire. Our regular daily meetings to provide up-to-date information about the fire, led by Marco Biester, were attended by Christoph von Maltzahn and he was therefore able to pass information onto our customers and sales staff. The company Polygonvatro was instructed to carry out fire damage restoration work on 21st February 2018.

Bernd Schönemeier coordinated the inventory and prioritisation of the affected goods in the temporary warehouse, actively supported in the process by quality assessment experts who evaluated the usability of the cleaned goods.

At the Eckenerstaße production site, production staff were busy order-picking the cleaned materials in such a way that the stoppages on our plants would remain as brief as possible.

On 22nd February 2018, we received a letter of support from Knorr-Bremse AG to be presented to our suppliers in which Knorr-Bremse, with its substantial market power, asked our suppliers to support us to the best of their ability in our reacquisition of raw materials and individual parts.

In the meantime, the appraiser appointed by the insurance company sent us a fundamental agreement on the part of the insurance company to cover our losses. This was an important milestone that did a lot to calm our nerves in a tense situation.

We found that the majority of our customers were very understanding about the supply issues that the fire had caused us. Nevertheless, we had and still have no desire to overstretch their patience, and on 14th March 2018, we therefore presented our customers with our action plan for remedying the fire damage in the mid- and long term and returning to orderly supply relationships.

While all these activities were going on, Dierk Dreyer set out to find a new warehouse space. Because the property market had become even more difficult since our last search for a new warehouse in 2017, this search became a genuine challenge. Yet Dierk Dreyer was able to find the warehouse space at Hägenstraße 4 in Hannover-Anderten, which the company has since acquired, by the last week of March. It was necessary to completely reconfigure this property as well, adapt the electrics and IT facilities and complete several modifications and renovation measures.

On 26th April 2018, we informed our customers that we would be moving to the new warehouse in the week 7th–13th May 2018, and that no deliveries could take place that week.

Nevertheless, thanks to the tireless cajoling and work of Michael Weper, we succeeded in safeguarding our automotive customers in particular against line stoppages through a number of individual deliveries.

This was especially important to the Board of Management. Because although nass magnet is not liable for losses resulting from line stoppages under these circumstances, given that the fire was an unavoidable event for which the company was not at fault, it is of course still in our interests to protect our customers against losses.

The greater the impact of the fire damage on our customers, the more inclined they will be in future to avoid such risks by means of second suppliers. Such a second supplier would cost us part of our turnover in future, as well as resulting in even greater price competition for us. This is why avoiding losses for our customers was always at the forefront of our efforts.

For the most part, we are still working within the schedule we communicated to our customers on 14th March 2018 and we hope to return to regular operations over the coming months. However, if you found yourself working to full capacity before a fire — as we were — then the reduction in production output caused by the fire can only be caught up by increasing operational capacity. Accordingly, the company is in the process of procuring additional production facilities and expanding our workforce.

Once again, it has become apparent that, despite a number of gloomy predictions, the nass magnet team — whether in Germany, Hungary, China or the USA — closes ranks in difficult situations. The nass magnet corporate group‘s shareholders, Supervisory Board and Board of Management would hereby like to sincerely thank everyone involved for their loyalty and commitment.

The fire made it necessary for us to depart from our standard procedures. The flow of materials came to a standstill and it was impossible to plan orders using our software. The dedication shown by everyone involved, the cohesion in the workforce and the clear goal of maintaining our ability to deliver expedited the problem-solving process and has made the company permanently stronger.

Even if there are sometimes tensions between individuals and departments in day-to-day working life, we stick together when it matters.

Something for which we can all be thankful. And this fact is not just reassuring — it is also one of the most important factors that will ensure our continued success in the future.

WE are the secret of our success!

Klaus Kirchheim

Chair of the Board of Management